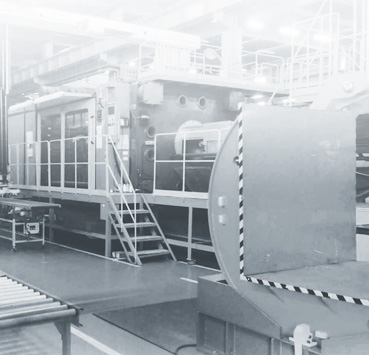

About AMP

Your Solution in Mold and Plastics.

Devoted to mold design, manufacturing and plastic injection production, and through close collaboration with all our co-workers who have been well-experienced elites in their fields.

Changing the Impossible

We believe that there is a boundless potential for plastics and their applications, so with continuous experimentation and research we breakthrough the preconceived limitations in both injection molding technology and physical products.